Bolts are fundamental components of building structures, machines, and equipment, and they come in different shapes, sizes, and types. In this article, we will overview ten types of bolts commonly used in construction and engineering.

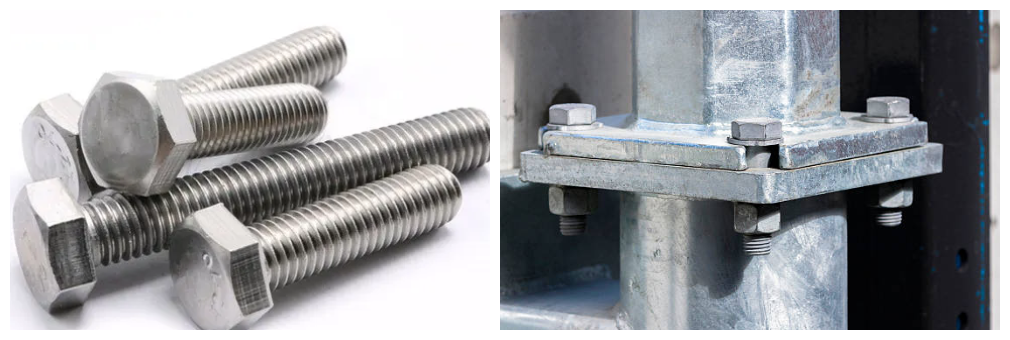

1. Hex Bolt: A Hex Bolt is a type of fastener that has a hexagonal-shaped head and a threaded shaft. It is commonly used for attaching two or more separate objects together, such as in construction or automotive applications. The head of the bolt has six flat sides that allow for easy tightening with a wrench or pliers, and the threaded shaft can vary in length depending on the specific application. Hex bolts are typically made of steel, and come in a range of sizes and thread patterns to suit different needs.

2. Flange Bolt: A flange bolt is a specialized type of bolt that is designed for use in applications where it is necessary to join two or more flange-bearing objects. It typically consists of a threaded shank that screws into a pre-drilled hole, and a flange head that extends out from the shank. The flange head is typically circular in shape, with a raised ridge around the outside edge to provide added surface area for clamping. This helps to distribute the pressure of the bolt more evenly across the surface of the flange, which can help to prevent damage or distortion of the flange over time. Flange bolts are commonly used in a variety of industries, including automotive, construction, and aerospace, and are available in a range of sizes and materials to suit different applications.

3. Carriage Bolt: A carriage bolt is a type of fastener used in construction and woodworking projects. It is a cylindrical bolt with a domed or countersunk head, and a square or hexagonal shank beneath the head. The shank is threaded at the tip, allowing for secure attachment to materials.

Carriage bolts are often used to attach wood to metal or to other wood pieces. They are also common in outdoor applications, such as attaching a railing to a deck or securing a fence post to a concrete base.

The design of the carriage bolt makes it well-suited for use in situations where a neat and finished appearance is desired, as the head of the bolt is often completely flush with the surface it is attached to. Its square or hexagonal shank also prevents it from spinning, providing added stability and security.

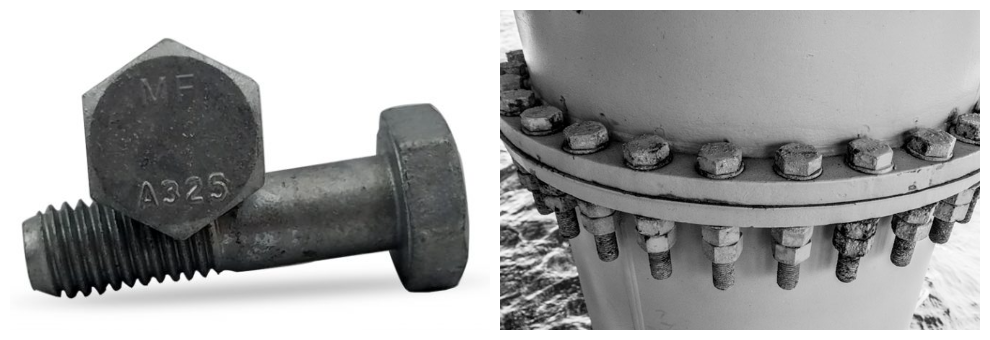

4. Heavy Bolt: Heavy bolts are high-strength fasteners that are designed to securely join two or more objects together. They are typically made from durable materials such as steel, titanium, or nickel, and can range in size from a few inches to several feet in length. These bolts are commonly used in heavy-duty applications that require significant tensile strength, such as in construction, machinery, and transportation industries. In addition, heavy bolts are often subject to rigorous testing and quality control procedures to ensure that they meet industry standards for strength and durability.

5. Eye Bolt: Eye bolts have a circular loop at one end and are commonly used in rigging applications that require lifting or securing objects. The eyelet serves as an attachment point for cables, ropes, or chains and is designed to be secured to a surface using a nut and washer. Eye bolts are commonly used in various applications such as rigging, hoisting, and suspension systems where the weight being supported requires a high-strength fastener. They are available in a range of sizes and load capacities to suit different requirements and can be made from various materials such as stainless steel, galvanized steel, or carbon steel. Proper installation and maintenance of eye bolts are crucial for ensuring safe and reliable performance.

6. Railway Bolt: A railway bolt is a specialized fastener used in railway track construction to secure rails and other components to sleepers or ties. It typically consists of a circular shank with a square head and a threaded end, which is inserted into a hole drilled in the sleeper and tightened using a nut. Railway bolts are made of high-strength steel to withstand the heavy loads and vibrations of trains passing over them. They are crucial components of railway infrastructure and must meet strict industry standards for safety and durability.

7. T Bolt: T bolts have a T-shaped head and are commonly used in applications where a secure, temporary hold is required.A T-bolt is a type of fastener that is commonly used in industrial and mechanical applications. It consists of a threaded bolt that has a T-shaped head, which provides a surface for a wrench or socket to grip and apply torque during installation and removal.

The T-bolt's threaded shaft is typically made from high-strength materials such as alloy steel or stainless steel, which enables it to withstand high levels of stress and tension. Additionally, the T-shaped head of the bolt allows for ease of installation and removal without the need for specialized tools.They are also frequently used in machinery and equipment, such as in the manufacturing and assembly processes for heavy equipment and machinery.

8. Expansion Bolt:An expansion bolt, also known as an anchor bolt or a wedge anchor, is a type of fastener that is used to secure materials to concrete or other masonry surfaces. It is specially designed to provide a secure and reliable connection by expanding the mechanical anchor once it is set in place.

The expansion bolt consists of a threaded stud, a washer, and a nut, all made from durable materials such as steel, stainless steel, or galvanized steel. The bolt is inserted into a pre-drilled hole in the concrete or masonry surface, and the washer and nut are placed on the exposed end of the stud. When the nut is tightened using a wrench or socket, the bolt expands against the walls of the hole, creating a tight grip that holds the material in place securely.

Expansion bolts are widely used in construction, engineering, and manufacturing applications where a strong and reliable anchorage is required. They offer several advantages over other types of fasteners, including high load-bearing capacity, high resistance to pull-out forces, and ease of installation. Their ability to expand and contract with changes in temperature and moisture levels also makes them ideal for use in a variety of environments and conditions.

9. Hanger Bolt: A hanger bolt, also known as a dowel screw, is a type of fastener that features a threaded rod with wood screw threads on one end and machine screw threads on the other end. The wood screw threads are designed to be driven into wood or other soft materials, while the machine screw threads allow the bolt to be fastened into metal, plastic, or other hard materials. Hanger bolts are commonly used for hanging items or fixtures from wooden structures or for attaching wooden legs to furniture. They are ideal for applications where a strong, secure connection is required between wood and other materials. Hanger bolts are typically made from steel, brass or stainless steel and come in a variety of lengths and diameters to suit different applications.

10. Shoulder Bolts: A hanger bolt is a specialized fastener designed for use in applications where a hanging load is required. It features a threaded shaft on one end that is inserted into a pre-drilled hole, while the other end has a wood screw thread that is used to secure the bolt to a wood surface.

Hanger bolts are commonly used in construction and furniture assembly, as they provide a strong, reliable connection between wood surfaces. They can also be used in electrical and plumbing applications, where they provide a secure mounting point for fixtures and equipment.

Hanger bolts are typically made of high-strength materials such as stainless steel or brass, which are resistant to corrosion and can withstand heavy loads. They come in a variety of sizes and thread configurations to accommodate different applications and loads.

Overall, hanger bolts are a versatile and essential component for any woodworking or construction project that requires a secure, hanging connection.