Consult your bolt customization experts

To provide customers with products and services of quality safety supply chain security, and cost saving.

Contact Us Now

Raw Material

Raw materials for fasteners are essential components used in the production of various types of fasteners, including screws, nuts, bolts, and other similarly threaded products. These raw materials are sourced from wholesale fastener suppliers, who specialize in providing high-quality materials that meet industry standards and specifications.

One of the most common types of fasteners is the hex head bolt and nut, which is frequently used in construction, manufacturing, and industrial applications. Raw materials for hex head bolts and nuts typically include alloys such as carbon steel, stainless steel, and titanium, as well as other materials like brass, bronze, and aluminum.

Brand materialss can ensure the stable physical and chemical properties of the bolts.

Cold forged

Our manufacturing units are well equipped with a contemporary lineup of imported high speed multi stationed Bolt formers and Part formers. This enables us to machine standard as well as special products with extreme extrusion, long lengths and bigger body diameters.

As below is our cold forging high speed Headers

MAX Ø 27 mm -- 6

MAX Ø 20 mm---10

MAX Ø 12 mm---14

MAX Ø 6 mm--- 3

In addition, there are over 15 rolling machines.

In special cold forged products, there are cold forged parts in accordance with customer samples and technical drawings, specially designed in engineering-method department.

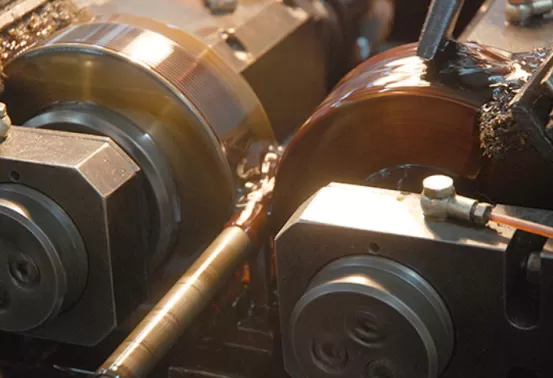

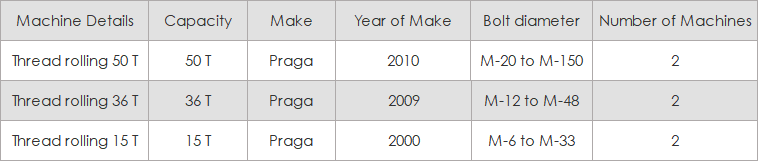

Thread Rolling

The thread rolling section has a wide array of high end machines, this part is very important, Only by ensuring the sharpness and distance of the threaded part can it be combined with the nut stronger and not loose.

Ever since we started manufacturing bolts we have always used thread rolling technology to make threads on our bolts and sockets, thread rolling is a better and much more effective way of performing threads on a bolt as compared to thread cutting, the advantage of thread rolling over thread cutting are tremendous, with thread rolling you get perfect fibre lines and unbroken fibres on the steel and when thread rolling is done after heat treatment they provide much more stronger threads as compared to thread rolling done before heat treatment.

DIN -ANSI- BS -iso can be meet , We guarantee that 100% threads will be tested with go-no-go gauges

Please see below the details of the CNC machines which are available in our factory.

Heat Treatment

Imported NADCAP certified continuous heat treatment furnaces with huge capacities have been installed to carry out processes including hardening, tempering, carburizing, nitriding and carbonitriding to achieve the desired mechanical properties.

It is this set up that allows us to produce high tensile fasteners in varying grades.as we know , 8.8 grade bolt --10.9 grade bolt-12.9 grade bolt.

Finish treatment

White bolt - blue bolt -yellow bolt, according the demand of customers, Zinc layer thickness is not same.

1-As below is the procedure of hot dipped gavanized:

1.The bolts will be dunked in caustic soda to remove any organic material, such as cutting oil and then quickly rinsed with water.

2.The bolts will be submerged in sulfuric acid. This process removes mill scale and helps the zinc bond to the headed anchor bolts by etching the steel.

3.After the acid bath, the bolts will be rinsed and then dipped in a flux solution which helps the zinc bond to the steel.

4.The bolts will be dipped in a tank of 840-degree molten zinc until the zinc has bonded to the steel.

5.After removing the bolts from the molten zinc, a high-speed spinner removes the excess zinc from the threads to allow for a quality nut-fit.

Dacromet Din6921 Flange Bolts

Dacromet is a high-performance coating used to protect metal surfaces from corrosion and wear. Dacromet Din6921 Flange Bolts are a specific type of bolt that has a flange attached to the head.This flange provides additionl bearing surface.

Din 933 Hot Dip galvanized Hex bolts

Din 933 Hot Dip galvanized Hex bolts are fasteners that have been treated with a process called Hot Dip galvanizing. This involves coating the bolts with a layer of zinc to protect them from corrosion and rust.

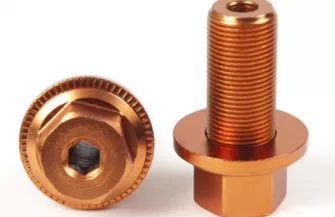

Copper plated hex bolt

Copper plated hex bolt refers to a hexagonal screw that has been coated with a layer of copper. This layer of copper provides protection against corrosion and enhances the bolt's aesthetic appeal.

DIN7984 Zinc Plated hex socket bolts

Galvanizing is a surface treatment method used to prevent rust and corrosion of metal objects. DIN7984 galvanized hexagon bolts are fasteners treated by this process, which are easy to install and apply torque using wrenches.

Din 933 Yellow Zinc Plated Hex bolts

Yellow zinc plating refers to the process of coating metal surfaces with a layer of zinc to protect them from corrosion. This coating provides additional durability and longevity when used with Din 933 yellow zinc-plated hexagon bolts.

Black Oxide DIN6921 Flange Bolts

Black Oxide is a chemical process that deposits a black oxide coating on metal parts to improve their corrosion resistance, durability, and appearance. Black Oxide DIN6921 Flange Bolts are bolts with a flange and a black oxide coating.

Stainless Steel Hex Bolt M12 x 50mm

Stainless steel is a durable and corrosion-resistant material that can be used in a variety of applications.Stainless steel hex bolts are a reliable and long-lasting choice for many different construction and manufacturing projects.

Plain heavy bolt Grade B7 Astm A193

Plain heavy bolts, Grade B7 ASTM A193 are a type of plain fastener that are specifically designed for high pressure and high temperature applications. These bolts are made from alloy steel and have been quenched and tempered for added strength.

Consult your bolt customization experts

To provide customers with products and services of quality safety supply chain security, and cost saving.

Contact Us Now